ISO Approved Suppliers

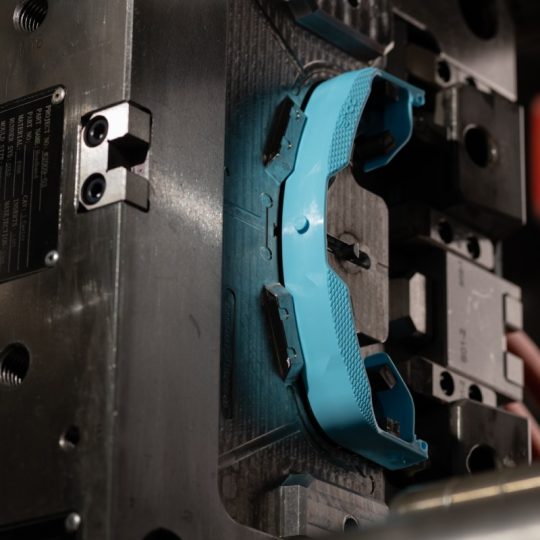

All our suppliers are ISO approved. But for us, that is just the starting point. Please contact us to understand how we specify, corroborate and validate every aspect of the mould manufacturing process.

All our suppliers are ISO approved. But for us, that is just the starting point. Please contact us to understand how we specify, corroborate and validate every aspect of the mould manufacturing process.

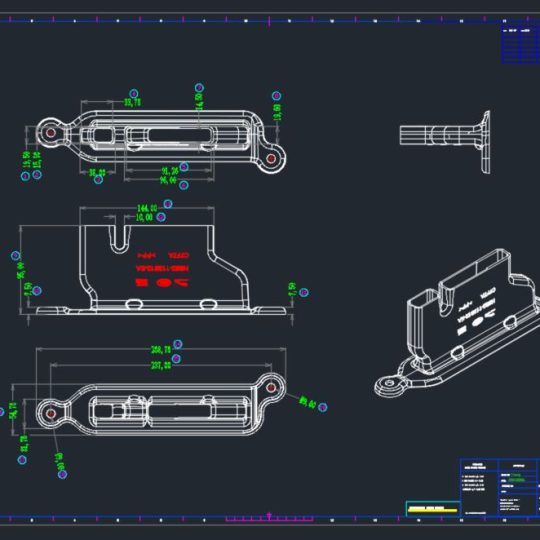

ISIR – We want to identify dimensional issues from the first trial, we do not wait for customers to measure parts. We create our own 2D drawings when customers cannot supply them.

Cavity Reports – We measure cavities as standard to validate the machining. We want to make sure any issues are captured early.

After Sales Support – Once you have the mould onsite at your premises, its covered by a Cortra Ltd warranty covering the materials and workmanship. Asian moulds with UK support underwriting the quality. We are happy to arrange engineering changes for tools in the UK or UK based chemical etching if this is also required.